Product description

This fully automatic heat shrink packaging machine is a new type of automatic continuous shrink packaging equipment, suitable for heat shrink packaging of food, beverages, candy, cultural supplies, arts and crafts, hardware tools, daily necessities, general merchandise, chemical products and other objects. After the heat shrink packaging machine, the items can be sealed, moisture-proof, and pollution-proof, and the goods can be protected from external impacts. It has a certain buffering capacity, especially when packaging fragile items, it can prevent the container from flying when it is broken. In addition, it can reduce the possibility of product disassembly and theft.

Working principle

1. Product feeding and positioning:

The product is automatically fed into the heat shrink packaging machine through a conveyor belt and accurately positioned in the equipment. According to the specifications and shape of the packaged items, the equipment automatically adjusts to meet different product requirements.

2. Sealing and wrapping:

In the sealing system, the heat shrink film will be automatically wrapped around the outside of the product. The packaging film is usually sealed at both ends by a sealing device to ensure that the packaging bag does not loosen. After this process is completed, the appearance of the package has been completely wrapped and formed into a bag-shaped package.

3. Heat shrinking process:

Hot air circulation or heating furnace: After the packaging film is wrapped, the product enters the heat shrink tunnel or heating furnace. The heat shrink tunnel heats the film by heating the air or by electric heat radiation. As the temperature rises, the heat shrink film begins to shrink and fits tightly to the appearance of the product. This process uses a temperature control system to ensure the stability of the heating temperature, so that the packaging film shrinks evenly and ensures the packaging effect of each product.

4. Cooling and finished product output:

When the shrink film is completely attached to the product, the product will pass through the cooling zone to ensure that the packaging film is cooled and solidified and remains tight. After cooling, the packaged products are automatically output via the conveyor belt and enter the subsequent packaging or boxing process.

Product features

1. Stainless steel heating tube is used, which is energy-saving and efficient (saving more than 15%)

2. The shrinking temperature and motor transmission speed are stable and adjustable, and the adjustment range is wide

3. The original roller self-rotation device can work continuously.

4. The bottom of the sealing and cutting shrinking machine can be adjusted at will. The casters are installed at the bottom and can be pushed at will. The height can be adjusted according to the size of the packaging.

Technical Parameters

|

Power supply: |

220v 50/60HZ |

|

Power: |

1.35kw |

|

Maximum packaging height: |

250mm |

|

Sealing line size: |

unlimited length, width 650mm |

|

Production capacity: |

0-30bags/min |

|

Air pressure: |

0.5Mpa |

|

Dimensions: |

1750x830x1460mm |

|

Machine weight: |

300kg |

Finished products show picture

Customer's visit

|

|

|

Product shipment

|

|

|

|

|

|

Previous Page:

Keywords:

Heat shrink machine

Heat shrink machine

Maximum packaging height: 250mm

Sealing line size: unlimited length, width 650mm

Production capacity: 0-30bags/min

Contact Us

Classification

Related Products

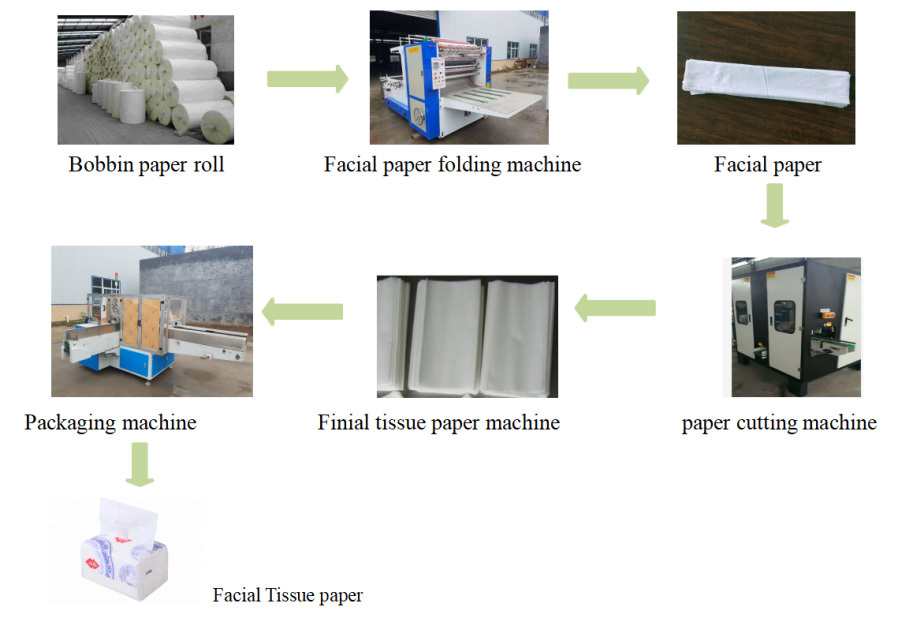

Final production of size: 200mm * 200mm

Customized size according to requirements

Raw paper weight(GSM):13-17g/m2

Automatic single log saw cutting machine

Finished products specification:70~110mm

Cutting length: 70~300mm

Double heads sealing packaging machine

Packing Film:CPP/PE/OPP/PT

Continuous plastic bag sealing machine

Packing speed:30-300 bags/min

Full Pillow Type Single Grain Packaging Machine

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.