-

-

Automatic Egg Tray Lines

-

FY-3*4 Egg Tray Machine(2500 pcs/h)

-

FY-4*8 Egg Tray Machine(4500 pcs/h)

-

FY-5*12 Egg Tray Machine(6500 pcs/h)

-

FY-6*8 Egg Tray Machine(7000 pcs/h)

-

Pulper

-

Small Drying Oven

-

Hot Pressing Shaping

-

Auto Stacking System

View More -

-

Egg Tray Machines

-

FY-1*3 Egg Tray Machine(1000 pcs/h)

-

FY-1*4 Egg Tray Machine(1500 pcs/h)

-

FY-3*4 Egg Tray Machine(2500 pcs/h)

-

FY-4*4 Egg Tray Machine(3000 pcs/h)

-

FY-4*8 Egg Tray Machine(4500 pcs/h)

-

FY-5*8 Egg Tray Machine(5500 pcs/h)

-

FY-5*12 Egg Tray Machine(6500 pcs/h)

-

FY-6*8 Egg Tray Machine(7000 pcs/h)

View More -

-

Pulp Molding Machines

View More -

Auxiliary Equipment

View More -

Molding Dies

View More -

Toilet Paper Rewinding Lines

View More -

Napkin Machine Lines

View More -

Facial Tissue Machine Lines

View More -

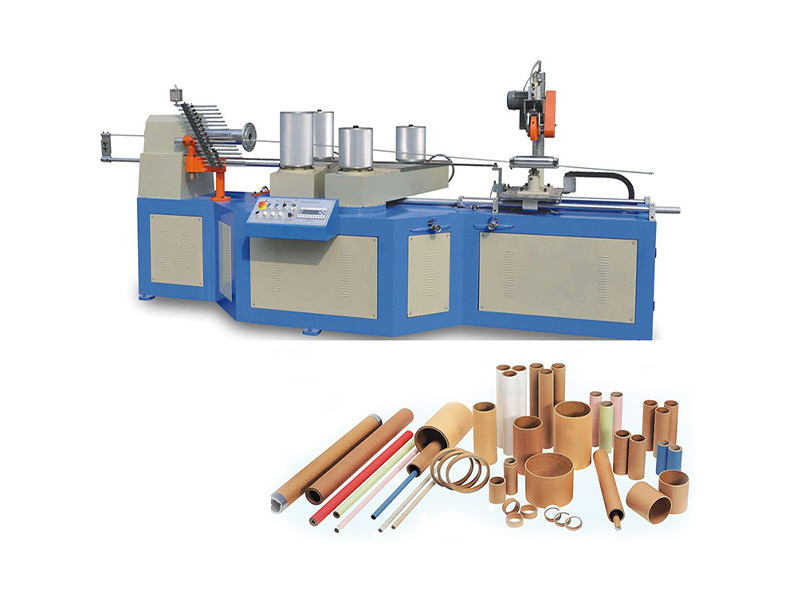

Paper Tube Machine Production Lines

View More -

Other Equipment

View More

Other

-

-

Other

Tableware/Industrial Packaging Solutions

Challenges Addressed:

The shift toward disposable eco-friendly tableware and industrial packaging demands machines that balance precision, speed, and compliance with food safety standards. Traditional plastic alternatives face regulatory bans and consumer rejection.

Our Solutions:

•Paper Tube Machines for Single-Use Tableware: Manufacture food-safe paper tubes for cutlery sets, straws, and disposable plates. Our machines support FDA-approved coatings for water and grease resistance.

•Customizable Egg Tray Systems: Produce protective trays for fragile items like glassware or electronics, using shock-absorbent pulp designs .

•High-Speed Napkin Folding Machines: Achieve 200–400 packs/minute with precision folding, suitable for restaurants and hotels.

Product Highlights:

•Hygienic Production: Machines comply with ISO 22000 standards, ensuring food-safe output.

•Adaptive Designs: Quick-change molds allow rapid shifts between product types (e.g., from napkins to paper cups).

•Energy-Efficient Drying: Conveyor-belt drying systems reduce energy use by 25% compared to traditional methods.

Why Partner With Us?

•End-to-End Automation: From raw material processing to smart packaging, our solutions minimize human intervention.

•Sustainability Focus: Machines align with global trends in circular economy and plastic reduction .

•Technical Support: Leverage IoT-driven predictive maintenance and remote troubleshooting .

Cases

Case Study: Saudi Client Facial Tissue Machine Production Line

In July 2021, a Saudi client approached us for a facial tissue machine production line. The client’s requirements included producing facial tissues sized at 200*200mm, achieving a machine speed of up to 180 meters per minute, incorporating embossed patterns on the final product, and using carton packaging for the finished goods.

Case Study: British Customer Paper Medical Bedpan Production Line (Egg Tray Making Machine)

In May 2021, a British client approached us for a customized paper medical bedpan production line using pure wood pulp as the raw material. The client required a specific style of paper medical bedpan tailored to their needs.

Recommended Products

Model:FY-180

Power:4.5kw

Embossing roller end:Steel to wool

Dimensions:3200*1100*1800 mm

Weight:800kg

Speed:180m/minute

Slitting capacity :80g-600g

Minimum cutting width:40mm

Maximum width of original paper:1600mm

Maximum diameter of base paper:1200mm

Maximum slitting diameter: 800mm

Tube Layer:3-16 layers

Tube Inner Diameter:Φ20~150mm

Tube Thickness:1~8mm

Cutting Method:Single Round Knife Cutting Without Resistance

Gluing Method:Single/Double Side Glue

Cutting Length:40-1500mm

Cutting speed:5-15 cut/min

Cutter feeding method:pneumatic

CONTACT

EMAIL:

Factory Address:

North of Provincial Highway 002 in the middle of Guhuang Line, Xiangyun Town, Wen County, Jiaozuo City, Henan Province, China

Operation Center:

501, Block A, Tenghe Building, University Science and Technology Park, Zhengzhou Hi-Tech Zone, Zhengzhou City, Henan Province, China

IMESSAGE

We are heppy to solve problems for customers

We will contact you within 2h after receiving your message

Copyright © 2025 Henan Fuyuan Machinery Manufacturing Co., Ltd.