Product description

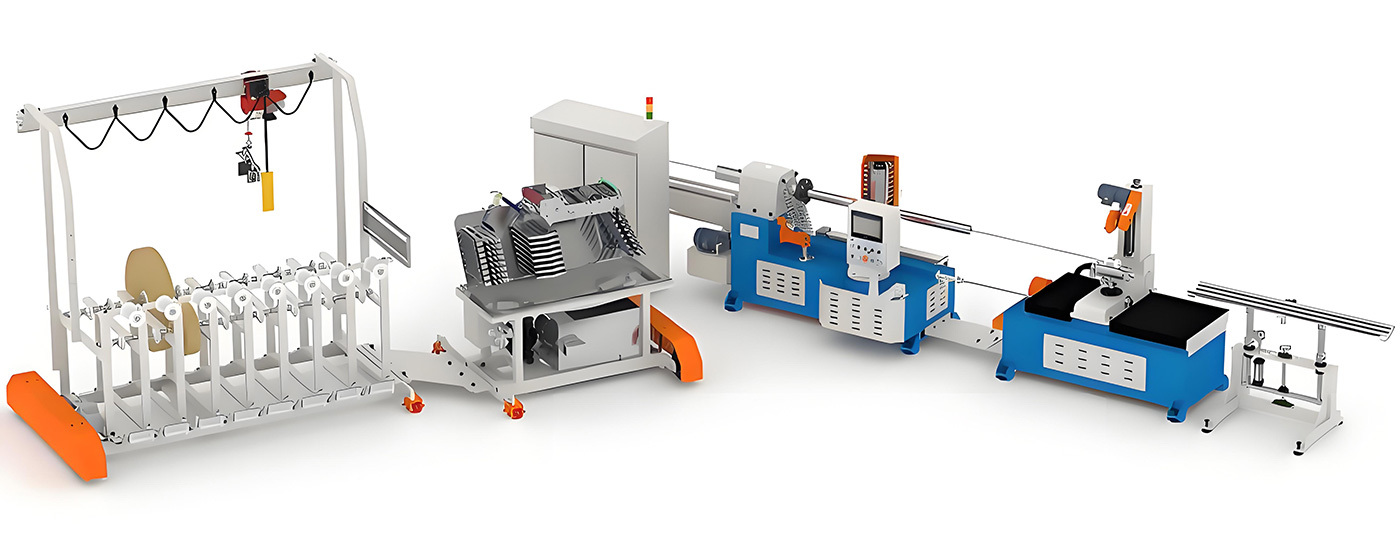

Paper Tube Machine is an automated equipment specialized in producing cylindrical paper products such as paper tubes, paper cores, paper cans, etc. Through winding, gluing, cutting and other processes, paper or paper tape is processed into paper tubes of different specifications, which are widely used in packaging, textile, printing, construction and other industries.

|

|

|

|

|

|

Working principle

The paper tube machine cuts the base paper into narrow strips, wraps them around the mandrel in a spiral or flat roll, glues them simultaneously, and cuts them into shape after hot air curing. It uses tension control and automation systems to ensure uniformity between layers, and produces paper tubes of different strengths and specifications to meet the needs of industry and packaging.

Product features

1. PLC control system is adopted to improve the cutting response speed, and the cutting length control is more accurate than before.

2. The main body is made of steel plate after cutting and welding. The frame is stable and not easy to deform, and the vibration is small.

3. The main drive adopts hardened tooth surface full oil bath chain drive, low noise, low heat, high speed and high torque.

4. The main motor adopts vector type high torque inverter speed regulation

5. The cutting length is adjustable, and the paper tube thickness is adjustable

Technical Parameters

|

Model |

2150A、2150B、2150C、2060C、4250B、4250C、4350B、4550B |

|

Diameter |

20-650mm |

|

Thickness |

1-25mm |

|

Gluing method |

Single/double-sided gluing |

|

Fixed length method |

Photoelectric (encoder optional) |

|

Mold fixing method |

Flange tightening |

Finished products show picture

Customer visits

|

|

|

|

|

|

Delivery site

|

|

|

|

|

|

Paper Tube Machine

Tube Layer:3-16 layers

Tube Inner Diameter:Φ20~150mm

Tube Thickness:1~8mm

Cutting Method:Single Round Knife Cutting Without Resistance

Gluing Method:Single/Double Side Glue

Contact Us

Classification

Related Products

Slitting capacity :80g-600g

Minimum cutting width:40mm

Maximum width of original paper:1600mm

Maximum diameter of base paper:1200mm

Maximum slitting diameter: 800mm

Cutting Length:40-1500mm

Cutting speed:5-15 cut/min

Cutter feeding method:pneumatic

Paper Roll: 2-3 Plies

Thickness: 0.25-1mm

Cutting Length: 65-820mm

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.