Product description

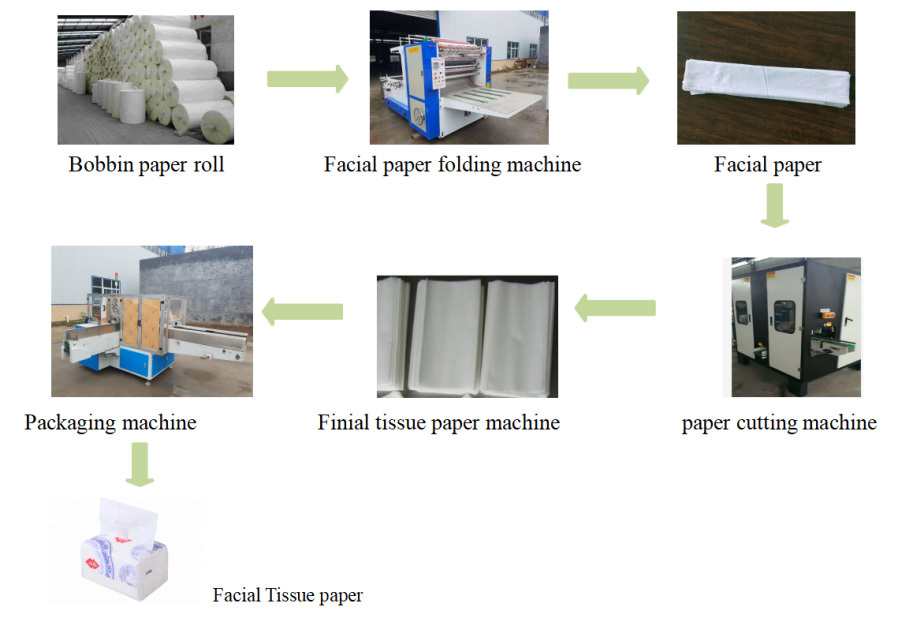

The facial tissue paper folding machine pumping is cut by the knife roll after cutting the raw paper, folded into a chain of rectangular cross tissues. machine with synchronous belt drive, transmission speed before and after the ratio, so that equipment suitable for a variety of base paper needs, greatly improving the quality and efficiency.

|

|

|

|

|

|

|

|

|

Working principle

Working principle: The production of tissue paper is mainly completed through vacuum adsorption folding, slitting and counting functions.

Product features

1. This machine adopts vacuum suction, automatic counting function stack, with a high speed, neatly folded, and easy operation.

2. The machine is equipped with a tension adjustment device to ensure the finished product size accuracy.

3. Broken paper automatic shutdown system, to avoid paperless or broken paper to produce waste.

Technical Parameters

|

Model |

FY-2L, FY-3L, FY-4L,FY-5L,FY-6L,FY-7L,FY-8L,FY-10L |

|

Raw paper weight (GSM) |

13-17g/m2tissue roll |

|

Raw paper width |

400mm~ 2000mm |

|

Raw paper diameter |

Maxφ1200 mm |

|

Paper core diameter |

φ76.2 mm |

|

Unfolding size |

200 mm*200 mm |

|

Folding size |

200mm*100mm |

|

Host Power |

3.5~5.5 kw |

|

Folding system |

vacuum absorption |

|

Vacuum system |

7.5~18kw |

|

Controller |

Electromagnetic speed |

|

Production speed |

80~ 110 meters/min |

|

Cutting system |

Pneumatic point cut,full cut |

|

Counting system |

automatic |

|

Voltage |

380V 50HZ 3phases /220V 60HZ 3phases |

Finished products show picture

Customer's visit

|

|

|

Product shipment

|

|

|

|

|

|

Facial tissue machine

Final production of size: 200mm * 200mm

Customized size according to requirements

Raw paper weight(GSM):13-17g/m2

Contact Us

Classification

Related Products

Automatic single log saw cutting machine

Finished products specification:70~110mm

Cutting length: 70~300mm

Double heads sealing packaging machine

Packing Film:CPP/PE/OPP/PT

Full Pillow Type Single Grain Packaging Machine

Continuous plastic bag sealing machine

Packing speed:30-300 bags/min

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.