Product description

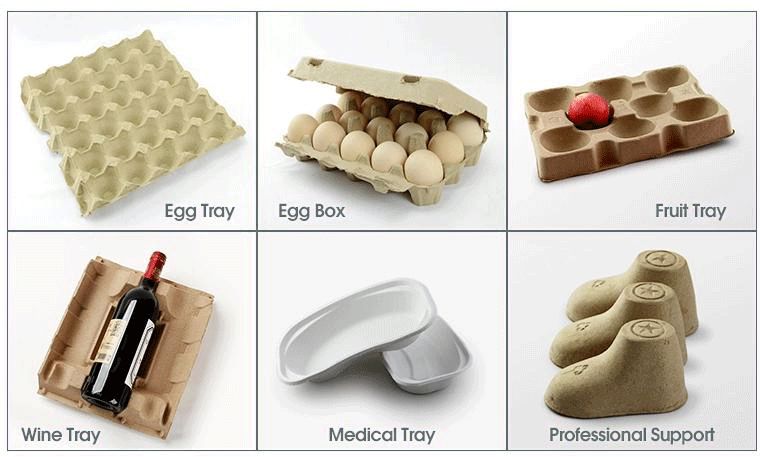

Paper Egg Box, Paper Wine Tray, Fruit Tray, Industrial Lining, Protection Paper Tray, Hot Pressing And Shaping Machine

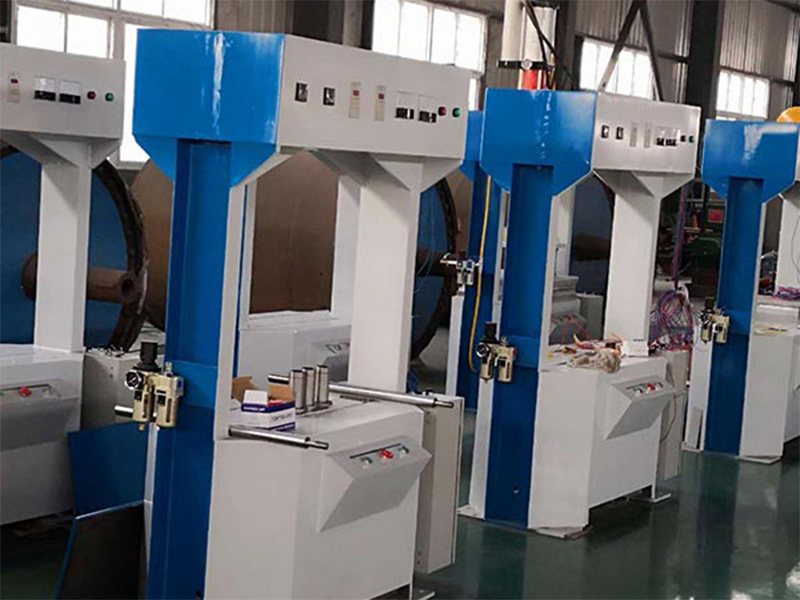

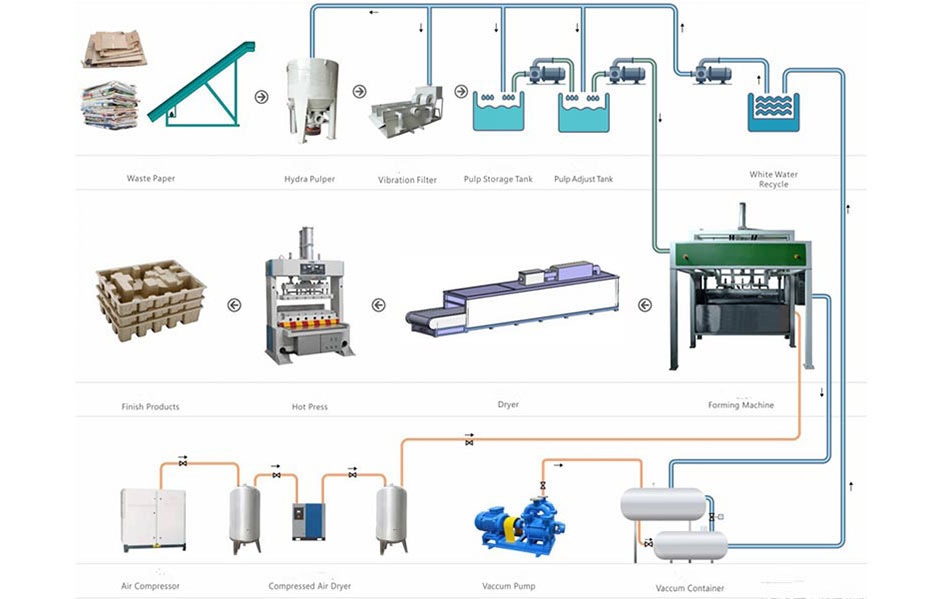

Pulp molding equipment mainly includes equipment for producing pulp molded products consisting of hydraulic pulpers, forming machines, shaping machines, plus supporting equipment such as air compressors, vacuum pumps, and pulp pumps. The hot press shaping machine is a device that smoothes the geometric shape of the dried paper support through the special hot press mold through the equipment heating, pressurizing and other actions.

|

|

|

|

|

|

Working principle

The egg tray machine production line mainly includes four system:

1.Cylinder

2. Guide rod

3. Frame

4. Adjusting plate

5. Upper template

6. Lower template

7. Triple body

8. Pressure regulating valve

The Open hot press mold customization mainly includes four system:

1.Sending design 3D drawings or samples

2.Select material

3.Open molds

4.Forming molds

Product features

Open mold customization, carefully selected materials, acid and alkali resistance, not easy to deform, stable and strong, complete specifications, source manufacturers, intimate after-sales.

1.It is processed by high-quality aluminum , with good extrusion performance, good strength, light weight, and corrosion resistance

2.The surface of the mold is fine and smooth, the color is bright, the hand feel is smooth and comfortable, the lines are smooth, and the craftsmanship is skillful.

3.The appearance is beautiful, the aluminum alloy is processed at one time, the whole is flawless, and the produced product is beautiful.

4.Recycling, can be used many times, stable performance, long service life, not easy to deform

5.Drawings and samples, support customized processing, many years of experience in mold opening customization, accurate mold opening.

Technical parameters

|

Machine Model |

Five Tons Hot Press |

|

Dimensions |

(Five Tons) 980×660×1920(Mm) |

|

Table Size |

(Single Cylinder) 660×450 (Mm) |

|

Workpiece Height That Can Be Produced |

≤150mm |

|

Rated Voltage |

Ac220V ± 10% |

|

Hot Pressing Time |

0~~6 Seconds Adjustable |

|

Power |

≤7Kw |

Finished products show picture

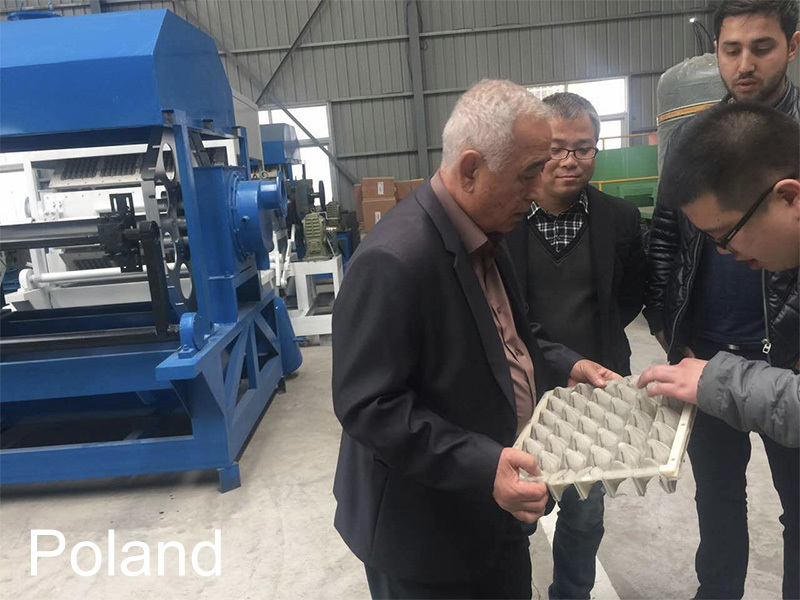

Customer's visit

|

|

|

|

|

|

Product shipment

|

|

|

|

|

|

Hot Pressing Shaping

Hot Press Mould:Customized

Working pressure:0.55~~0.65MPa

Mold High:≤150mm

Contact Us

Classification

Related Products

FY-1*3 Egg Tray Machine(1000 pcs/h)

Capacity: 1000 Pieces/Hour

Egg Tray Mould: Customized

Dryer: Natural Sun Dryer

FY-1*4 Egg Tray Machine(1500 pcs/h)

Capacity:1500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Sun Drying

FY-3*4 Egg Tray Machine(2500 pcs/h)

Capacity:2500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

FY-4*4 Egg Tray Machine(3000 pcs/h)

Capacity:3000 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

FY-4*8 Egg Tray Machine(4500 pcs/h)

Capacity:4500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.