Product description

Molded Pulp Packaging & Egg Tray/Carton Making Machine. Fuyuan offers a comprehensive range of over 100 specifications of pulp molding machinery, including high-quality egg tray production lines, molded pulp packaging lines, and other pulp molded product lines. We provide both fully automatic and semi-automatic production lines with varying capacities to meet diverse customer needs. Our company boasts complete facilities for product development, machine manufacturing, mold processing, and production process testing. We offer turnkey production lines, including equipment and molds, along with integrated technical services such as process support and personnel training. Upon purchasing our complete plant equipment, customers receive production process formulas and technical guidance to ensure successful mass production. Recommended Site Area: Production workshop 100 sqm, drying area 1000 sqm, warehouse 300 sqm or more. Suitable for producing various types of egg trays, egg cartons, shoe supports, fruit trays, and molded pulp packaging.

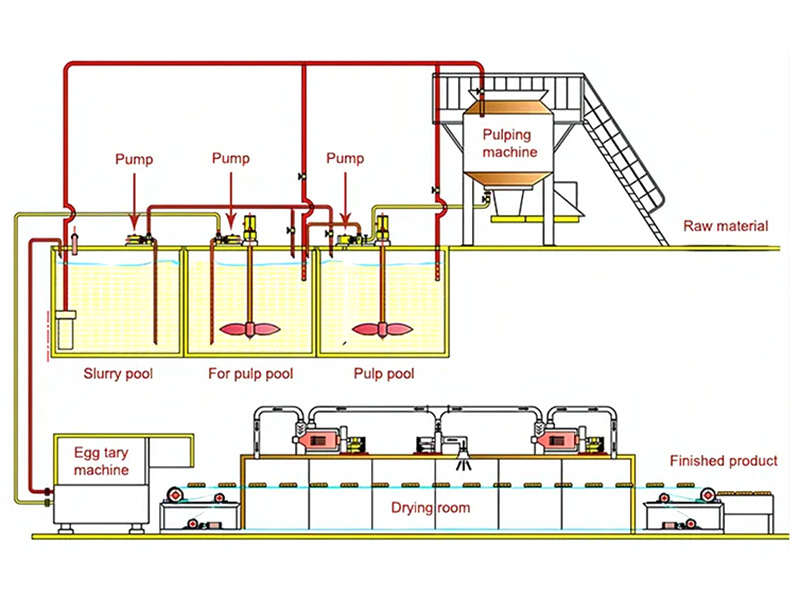

Working principle

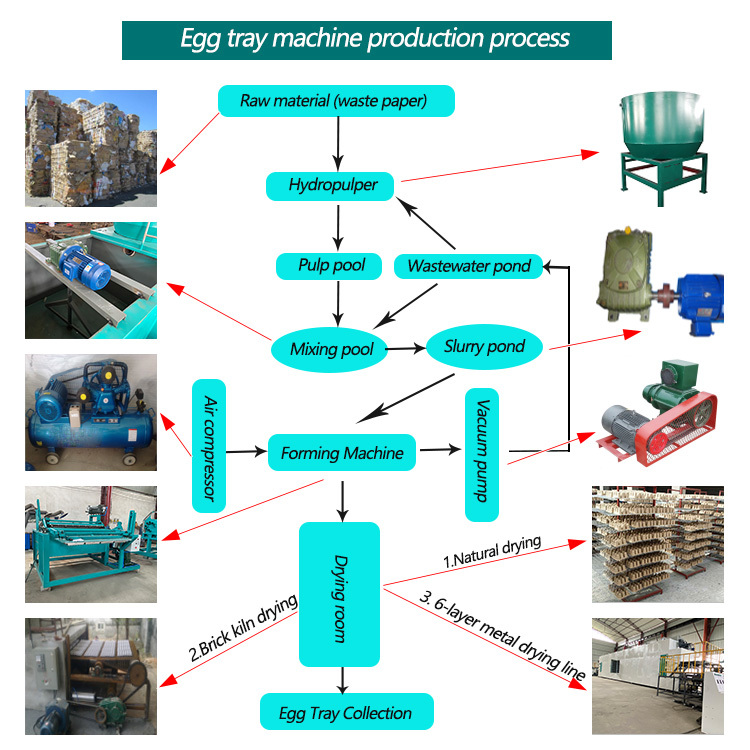

The molded pulp egg tray production process involves the following steps:

1.Pulping: Waste paper and water are mixed in a pulper for 20 minutes to create pulp.

2.Molding: The bottom mold is lowered into the pulp slurry, and vacuum suction forms the egg tray shape on the mold surface. The bottom mold then rises and meets the reciprocating top mold, where mechanical pressing removes excess water to finalize the tray's form.

3.Drying: Egg trays are dried using hot air or natural drying. Drying options include box drying (for small-scale production), brick kiln drying, and multi-layer metal drying.

4.Finishing: Optional finishing equipment includes an automatic stacking machine, hot press shaping machine, and egg baler.

The molded pulp packaging production line mainly includes 4 system:

1.Pulping System

2.Molding System

3.Drying System

4.Hot Press System

|

|

Product features

Equipment Structure and Operation

1.Reciprocating Structure: Bottom mold moves up/down to absorb pulp; top mold moves back/forth to release products.

2.Automated Production: Products are automatically produced and transferred to the drying line.

Technical Parameters

1.Template Size: 1600x800 mm; holds 6 sets of 30 egg tray molds.

2.Cycle Time: 12-18 seconds per cycle (for a 75g egg tray).

3.Capacity: 1200-1500 pieces per hour (for 30-pack egg trays).

Control System

1.PLC Intelligent Control: Full production process managed via PLC with HMI for parameter setting, production planning, counting, and alarms.

2.Automatic Cleaning: Features automatic mold washing and burr removal.

3.Stainless Steel Components: Pulp bucket and control box made from SUS304 stainless steel.

4.PLC + Touch Screen: User-friendly operation via touch screen HMI.

Component Quality

1.Electrical Components: High-quality brands like Inovance and CHNT.

2.Pneumatic Components: Reliable brands such as SMC/ARK.

Additional Benefits

Eco-Friendly: Uses various waste paper materials; biodegradable products.

High Efficiency: Automated high-output production.

Effective Protection: Provides robust protection for eggs, fruits, etc.

Cost-Effective: Low raw material and production costs.

Technical parameters

|

Model |

FY-R2Pulp Molding Machine |

|

Processing Type |

Pulp Molding Equipment |

|

Production Capacity |

1200-1500 pcs/hour |

|

Total Power |

60 kW |

|

Weight |

5000 kg |

|

Waste Paper Consumption |

120 kg/hr |

|

Water Consumption |

300 kg/hr |

|

Workshop Area |

100 sqm |

|

Voltage |

220V/380V |

|

Raw Material |

Any waste paper (newspapers, magazines, books, A4 paper, etc.) |

|

Mold Material |

Plastic or aluminum |

|

Mold Size |

600*800 mm × 2 |

|

Drying Method |

Customizable |

|

Finished Products |

Egg trays, fruit trays, shoe trays, wine trays, industrial product packaging, etc. |

|

Quality Standards |

CE, ISO |

Finished products show picture

Customer's visit

|

|

|

|

|

|

Product shipment

|

|

|

|

|

|

Auto Stacking System

Capacity:1200-1500 pieces/hour

Mould:600*800*2

Dryer:Customized

Contact Us

Classification

Related Products

Capacity:360-400 pieces/hour

Mould:600*800

Dryer:Customized

Capacity:1200-1500 pieces/hour

Mould:600*800*2

Dryer:Customized

FY-1*3 Egg Tray Machine(1000 pcs/h)

Capacity: 1000 Pieces/Hour

Egg Tray Mould: Customized

Dryer: Natural Sun Dryer

FY-1*4 Egg Tray Machine(1500 pcs/h)

Capacity:1500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Sun Drying

FY-3*4 Egg Tray Machine(2500 pcs/h)

Capacity:2500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.