Product description

Single-channel large orbit tissue cutting is a special design. It is used to automatically cut and fold the tissue paper products. The design and manufacture of the whole machine adopt the latest electrical technology and servo drive technology, greatly enhancing the cutting stability and improving the quality of paper cutting. Automatic single log saw cutting machine is an automated equipment specially used for the paper production line, which can accurately cut large rolls of toilet paper base paper. Through efficient tool systems and precise control technology, it ensures that the cutting size of each section of toilet paper is uniform and neat, meeting the packaging requirements of different needs. The equipment is easy to operate and stable in operation, which greatly improves production efficiency and product quality, and is widely used in the toilet paper production industry.

|

|

|

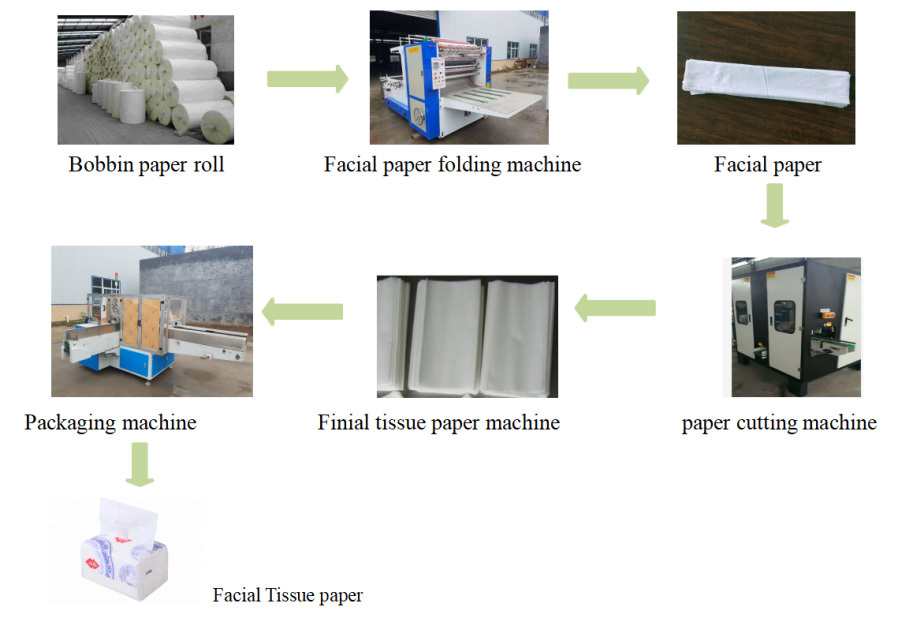

Working principle

The cutter is driven by mechanical transmission to cut paper in a cycle and is controlled by PLC, which greatly saves manual operation, improves efficiency and has high cutting precision.

Product features

1.It transports the whole piece of facial tissue to the paper cutter, and cuts it to a predetermined length with a large round knife, without squeezing or damaging the facial tissue.

2.The sharpening area is equipped with a dust suction device to remove dust and reduce temperature;

3.The knife sharpening machine has an automatic feeding function, which is convenient for sharpening;

4.Use compressed air to cool the sharpening area.

Technical Parameters

|

Raw material tissue paper long |

Min 500mm |

|

Work speed |

30~200cuts/minute |

|

Finished products specification |

60~550mm |

|

Height of paper |

60~100mm |

|

Total Power |

6.8 kw |

|

Voltage |

380V 50HZ3Phase 380V 50HZ 3 |

|

Measure |

3500*1700*2500 mm |

|

Weight |

2300kg |

Finished products show picture

Customer's visit

|

|

|

|

|

|

Product shipment

Automatic single log saw cutting machine

Finished products specification:70~110mm

Cutting length: 70~300mm

Contact Us

Classification

Related Products

Final production of size: 200mm * 200mm

Customized size according to requirements

Raw paper weight(GSM):13-17g/m2

Double heads sealing packaging machine

Packing Film:CPP/PE/OPP/PT

Full Pillow Type Single Grain Packaging Machine

Continuous plastic bag sealing machine

Packing speed:30-300 bags/min

Capacity : 3 tons /8hours

Embossed Pattern : Customized

Automatic : Fully automatic production line

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.