Product description

The small-scale egg tray drying machine is designed for rapid drying of wet egg trays in production lines. It is ideal for family workshops, small poultry farms, or medium-sized pulp molding factories. With its compact size, low energy consumption, and user-friendly operation, it effectively replaces traditional sun-drying methods, improving production efficiency and product quality.

Key advantages

1.Energy Efficiency & Eco-Friendly: Achieves over 60% thermal efficiency, reducing energy consumption by 30% compared to traditional brick kiln drying.

2.Flexible Adaptation: Supports hybrid drying modes (natural + mechanical) to lower initial investment costs.

3.Easy Maintenance: Modular design with extended cleaning cycles (approx. once per week). Critical components (e.g., fans, heating tubes) are replaceable in minutes.

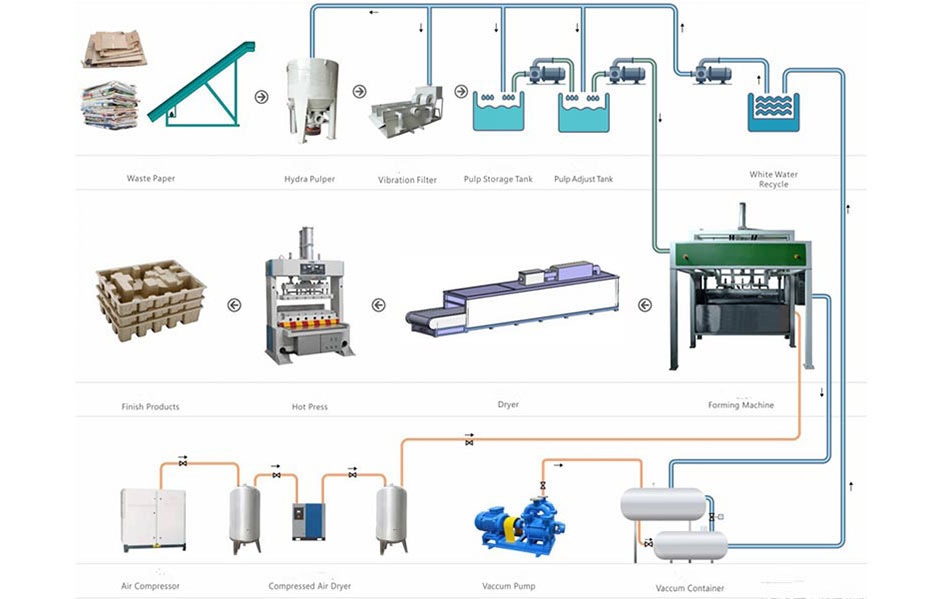

Working principle

1.Hot Air Circulation Drying:

• A heat source (e.g., burner or electric heating element) warms the air, which is then evenly distributed into the drying chamber via a fan.

• Wet egg trays are placed on multi-layer mesh belts or trays. Hot air penetrates the pulp fiber layers, accelerating moisture evaporation.

• Humid air is expelled through an exhaust system, while fresh hot air replenishes the chamber, maintaining continuous circulation.

2.Multi-Stage Temperature Control:

• Initial High-Temperature Stage (180°C–220°C): Rapidly removes surface moisture to shorten drying time.

• Intermediate Soaking Stage (120°C–150°C): Promotes internal moisture diffusion to prevent deformation or cracking.

• Final Low-Temperature Stage (80°C–100°C): Stabilizes product shape and ensures uniform drying.

Product features

1.Compact Design: Utilizes a multi-layer mesh belt structure or modular metal drying chambers, with a small footprint (typical dimensions: 2.3m × 1.2m × 1.7m), suited for small-scale production environments.

2.Multi-Fuel Compatibility: Supports coal, biomass pellets, natural gas, or electricity as heat sources. Equipped with an intelligent temperature control system (adjustable range: 80°C–220°C) to adapt to regional energy availability.

3.Automated Control: Integrated PLC system for precise regulation of temperature, humidity, and airflow. Some models include automatic ash-cleaning and fault alarm functions.

|

Parameter |

Value/Description |

|

Capacity |

1,000–1,500 pieces/hour (compatible with egg tray molding machines producing 1,000–2,000 pieces/hour) |

|

Heat Source |

Coal, biomass pellets, natural gas, electricity (optional) |

|

Power Consumption |

30–38 kW (includes fan and heating system) |

|

Temperature Range |

80°C–220°C (adjustable by stage) |

|

Drying Time |

4–8 hours (adjustable based on tray thickness and initial moisture content) |

|

Fuel Consumption |

Coal: 22–32 kg/h; Natural gas: 18–28 m³/h (based on 1,000 pieces/hour output) |

|

Dimensions |

Approx. 2.6m × 2.2m × 1.9m (includes conveyor belt) |

|

Temperature Uniformity |

≤±3°C (ensured by multi-layer temperature control system) |

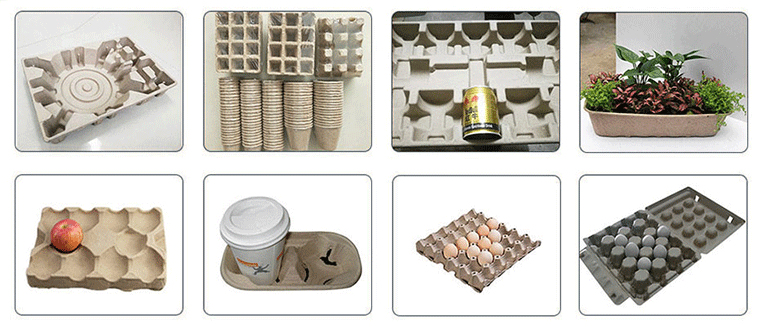

Finished products show picture

Customer's visit

|

|

|

|

|

|

Product shipment

|

|

|

|

|

|

Small Drying Oven

Heat Source:Coal, biomass pellets, natural gas, electricity (optional)

Power Consumption:30–38 kW (includes fan and heating system)

Contact Us

Classification

Related Products

FY-4*4 Egg Tray Machine(3000 pcs/h)

Capacity:3000 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

FY-4*8 Egg Tray Machine(4500 pcs/h)

Capacity:4500 pieces/hour

Egg Tray Mould:Customizable

Dryer:Natural Drying, Brick Kiln Drying, Metal Drying

Capacity:360-400 pieces/hour

Mould:600*800

Dryer:Customized

Capacity:1200-1500 pieces/hour

Mould:600*800*2

Dryer:Customized

Suitable Molding Machine:FY-4*4

Mould Style:Customized

Mold Material:Aluminium

Customer FAQ

Do you offer after-sales service?

Yes, indeed! We provide comprehensive after-sales support:

▸ 24/7 Remote Technical Assistance: Our service team is always available to guide you.

▸ On-Site Engineer Visits: If needed, we can send our engineers to your location for installation and staff training. (Customer covers travel expenses.)

▸ Spare Parts Priority: We ensure you get replacement parts quickly.

What about the quality of your machines?

Our machines are built to high standards:

▸ Certifications: We hold ISO 9001:2015, CE, and TUV certifications.

▸ Rigorous Testing: Each machine undergoes extensive testing before leaving our factory, guaranteeing top quality.

Are your products certified?

Absolutely. All our products are ISO and CE certified. We have a dedicated quality control department to inspect every machine before shipment.

Are you a manufacturer or a trading company?

We are a professional OEM manufacturer, specializing in:

▸ Egg tray machines (1,000–8,000 pcs/hr)

▸ Tissue and napkin paper production lines

▸ Custom pulp molding systems

▸ Paper core and tube machines.

▸ Facial tissue machines.

▸ Toilet paper machines.

▸ Packing machines.

▸ Paper straw machines.

We have been serving customers in over 80 countries across Asia, Africa, and South America since 1984, and have a strong reputation worldwide.

What is the warranty on your machines?

We provide a 12-month warranty covering:

▸ Main machine structures

▸ Motors and gearboxes

(Note: Molds, belts, and proximity sensors are not included.)

What is the delivery time?

Our standard delivery time is 30 days.

Expedited Options:

▸ For 20-day priority production, a 15% surcharge applies.

▸ We offer FOB/CIF shipping from Qingdao Port.

Can I customize the FY-1*3 1000pcs/hr egg tray system?

Yes, you can! We offer customization options:

▸ Solar or gas-powered drying

▸ 1–4 forming molds

▸ PLC automation upgrades

What payment terms do you accept?

We offer flexible payment options:

▸ 30% deposit, 70% before shipment (TT)

▸ 100% LC at sight

▸ Negotiable installment plans.