-

-

Automatic Egg Tray Lines

-

FY-3*4 Egg Tray Machine(2500 pcs/h)

-

FY-4*8 Egg Tray Machine(4500 pcs/h)

-

FY-5*12 Egg Tray Machine(6500 pcs/h)

-

FY-6*8 Egg Tray Machine(7000 pcs/h)

-

Pulper

-

Small Drying Oven

-

Hot Pressing Shaping

-

Auto Stacking System

View More -

-

Egg Tray Machines

-

FY-1*3 Egg Tray Machine(1000 pcs/h)

-

FY-1*4 Egg Tray Machine(1500 pcs/h)

-

FY-3*4 Egg Tray Machine(2500 pcs/h)

-

FY-4*4 Egg Tray Machine(3000 pcs/h)

-

FY-4*8 Egg Tray Machine(4500 pcs/h)

-

FY-5*8 Egg Tray Machine(5500 pcs/h)

-

FY-5*12 Egg Tray Machine(6500 pcs/h)

-

FY-6*8 Egg Tray Machine(7000 pcs/h)

View More -

-

Pulp Molding Machines

View More -

Auxiliary Equipment

View More -

Molding Dies

View More -

Toilet Paper Rewinding Lines

View More -

Napkin Machine Lines

View More -

Facial Tissue Machine Lines

View More -

Paper Tube Machine Production Lines

View More -

Other Equipment

View More

Other

-

-

Other

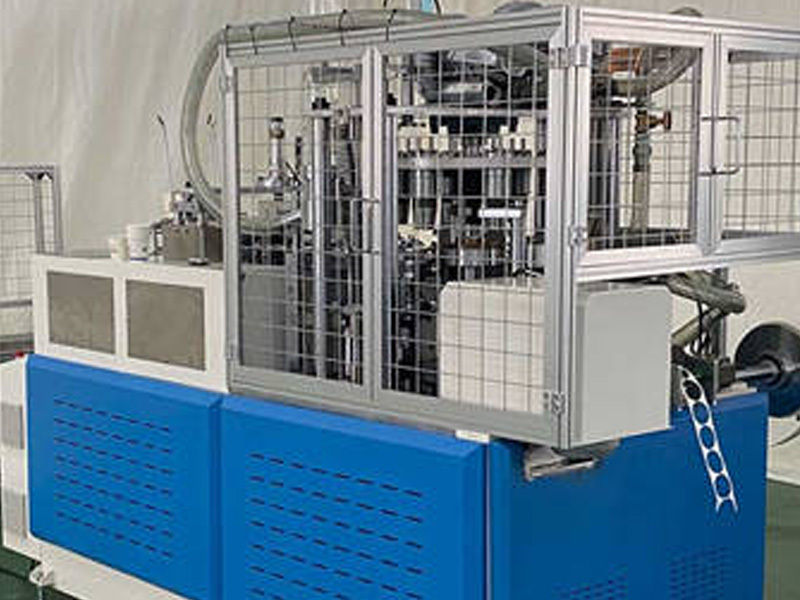

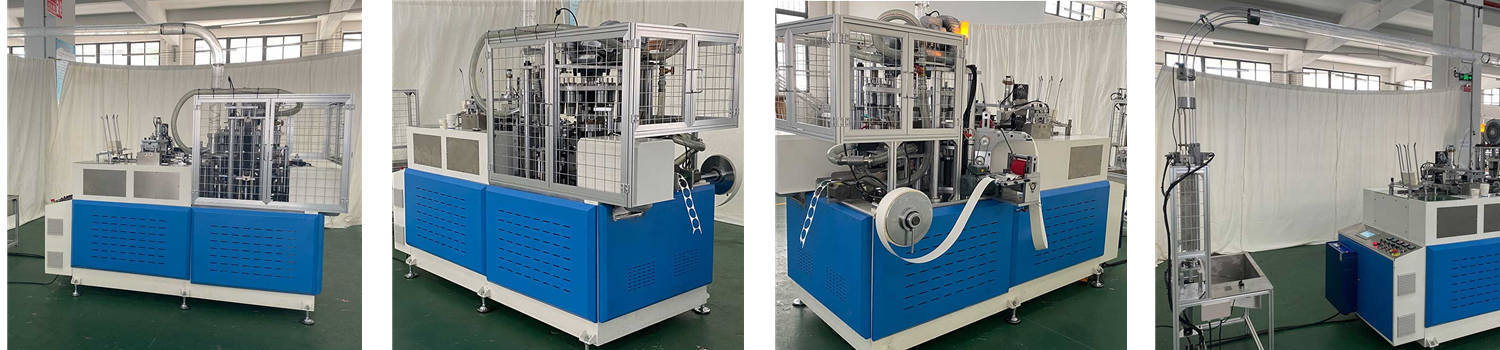

Paper cup production line

2025-03-04

A. Paper cup automatic forming machine has the advantages of high performance, high efficiency and high quality.

B. The indexing of the station plate adopts an open cam, and the advanced high-precision cam drive and gear transmission make the forming of each station accurate.

C. Maintenance and lubrication are more convenient and simpler than the closed splitter. The transmission parts in the machine have large space, is easy to operate and maintain, and are superior to similar products on the market in all aspects.

D. Servo tracking backing paper ensures the size of the cup backing paper, ensures the size of the cup backing paper and effectively saves raw materials.

E. Human-machine interface PLC system controls the long-term stable operation of the whole machine.

F. The reasonable setting of automatic counting cup table can replace the busy work of manual labor.

G. The automatic paper cup forming machine has over-cup detection, cup cylinder forming detection, and automatic shutdown alarm for faults.

H. This paper cup machine adopts a fully enclosed structure, waste and dust are not easy to fall into the machine, and the inside of the machine can be kept clean and tidy, so as to ensure the efficient operation of mechanical transmission.

I. Using ultrasonic welding system, multiple fans operate at the same time, increase heat dissipation, speed up cooling, and keep the machine at a proper temperature during operation.

CONTACT

EMAIL:

WHATSAPP/WECHAT:

Factory Address:

North of Provincial Highway 002 in the middle of Guhuang Line, Xiangyun Town, Wen County, Jiaozuo City, Henan Province, China

Operation Center:

501, Block A, Tenghe Building, University Science and Technology Park, Zhengzhou Hi-Tech Zone, Zhengzhou City, Henan Province, China

IMESSAGE

We are heppy to solve problems for customers

We will contact you within 2h after receiving your message

Copyright © 2025 Henan Fuyuan Machinery Manufacturing Co., Ltd.